Knot Holder

Collaboration

Liberal Office

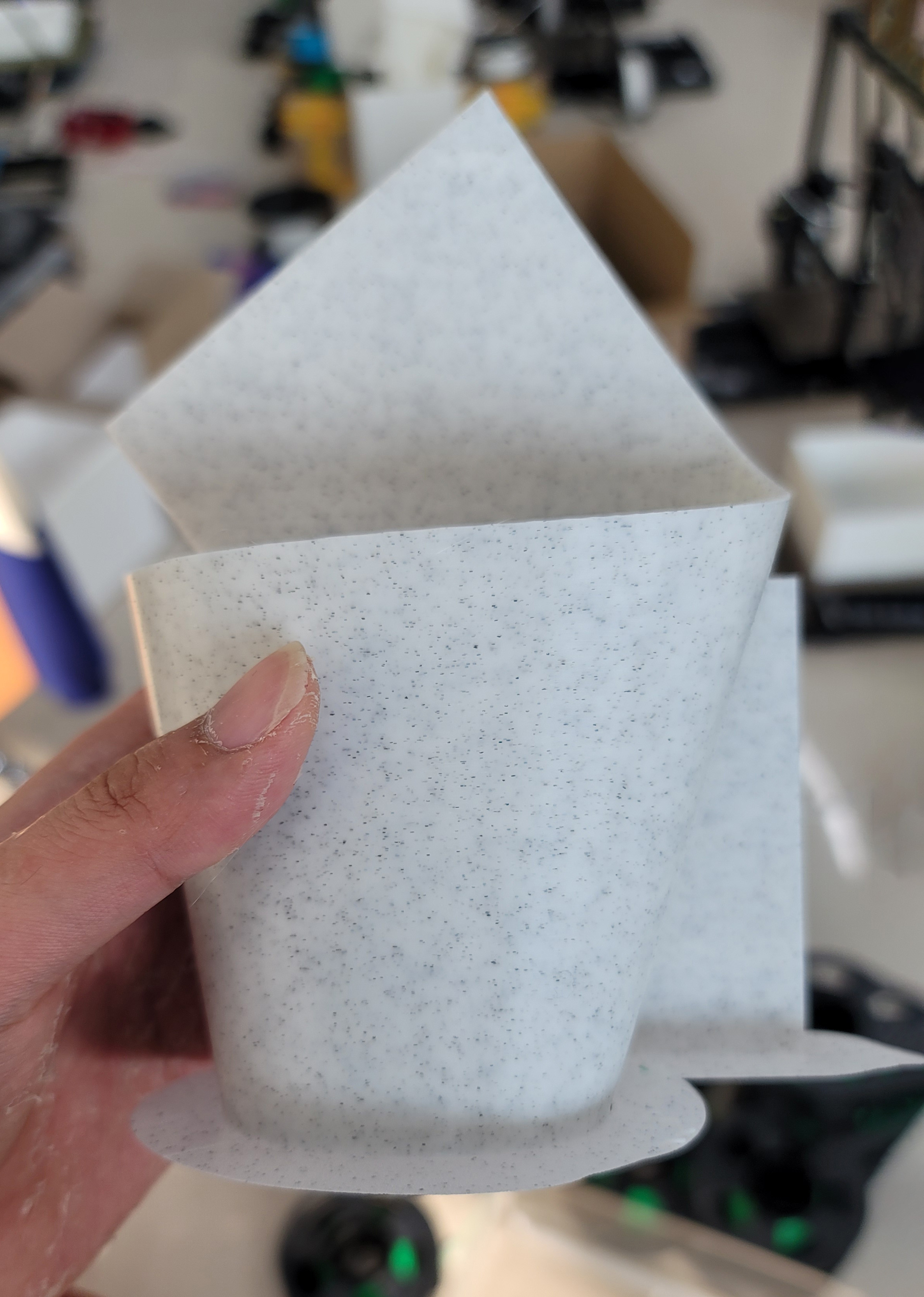

Material

Marble-textured filament, copper-filled filament

Intention

Captured functionality in the moment of rolling the surface

Tao Te Ching - Lao Tzu - chapter 11

Thirty spokes share the wheel's hub;

It is the center hole that makes it useful.

Shape clay into a vessel;

It is the space within that makes it useful.

Cut doors and windows for a room;

It is the holes which make it useful.

Therefore profit comes from what is there;

Usefulness from what is not there.

Thirty spokes share the wheel's hub;

It is the center hole that makes it useful.

Shape clay into a vessel;

It is the space within that makes it useful.

Cut doors and windows for a room;

It is the holes which make it useful.

Therefore profit comes from what is there;

Usefulness from what is not there.

Capture functionality in the moment of rolling a surface:

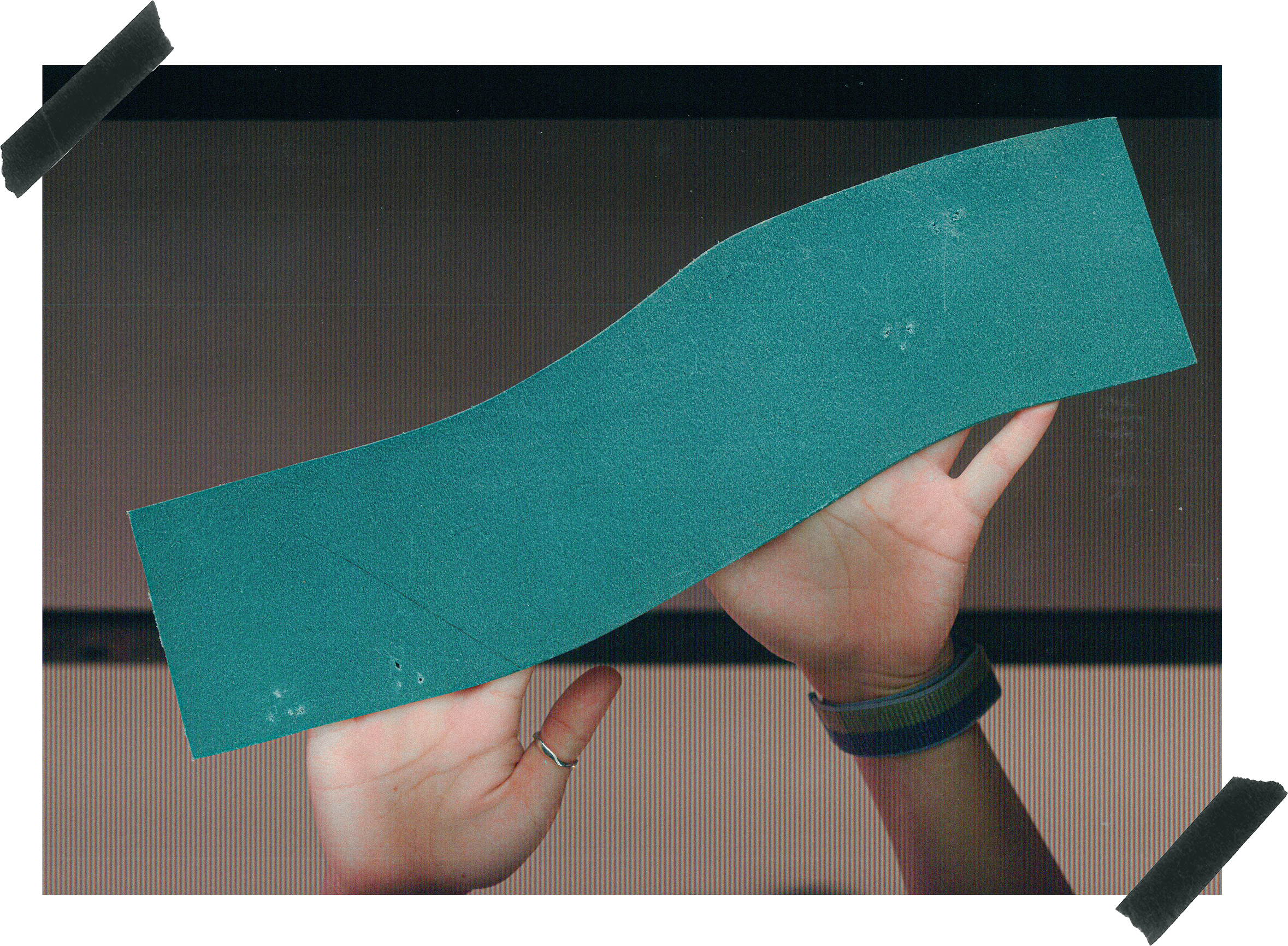

In my initial attempt, I focused on using leather with distinctive textures on both sides but overlooked its unique properties throughout the process. While traditional leather crafting methods emphasize handcrafting and design techniques to achieve high-quality results, shaping the curved surface proved challenging due to the material's softness. Additionally, the high production cost limits its feasibility for small-quantity sales.

In my initial attempt, I focused on using leather with distinctive textures on both sides but overlooked its unique properties throughout the process. While traditional leather crafting methods emphasize handcrafting and design techniques to achieve high-quality results, shaping the curved surface proved challenging due to the material's softness. Additionally, the high production cost limits its feasibility for small-quantity sales.

I used mixture filaments to mask the plastic-like appearance, aiming to achieve a craft-like finish resembling ceramic or leather. I also adjusted the 3D modeling data to enable printing the final product without a support structure, minimizing printing errors.